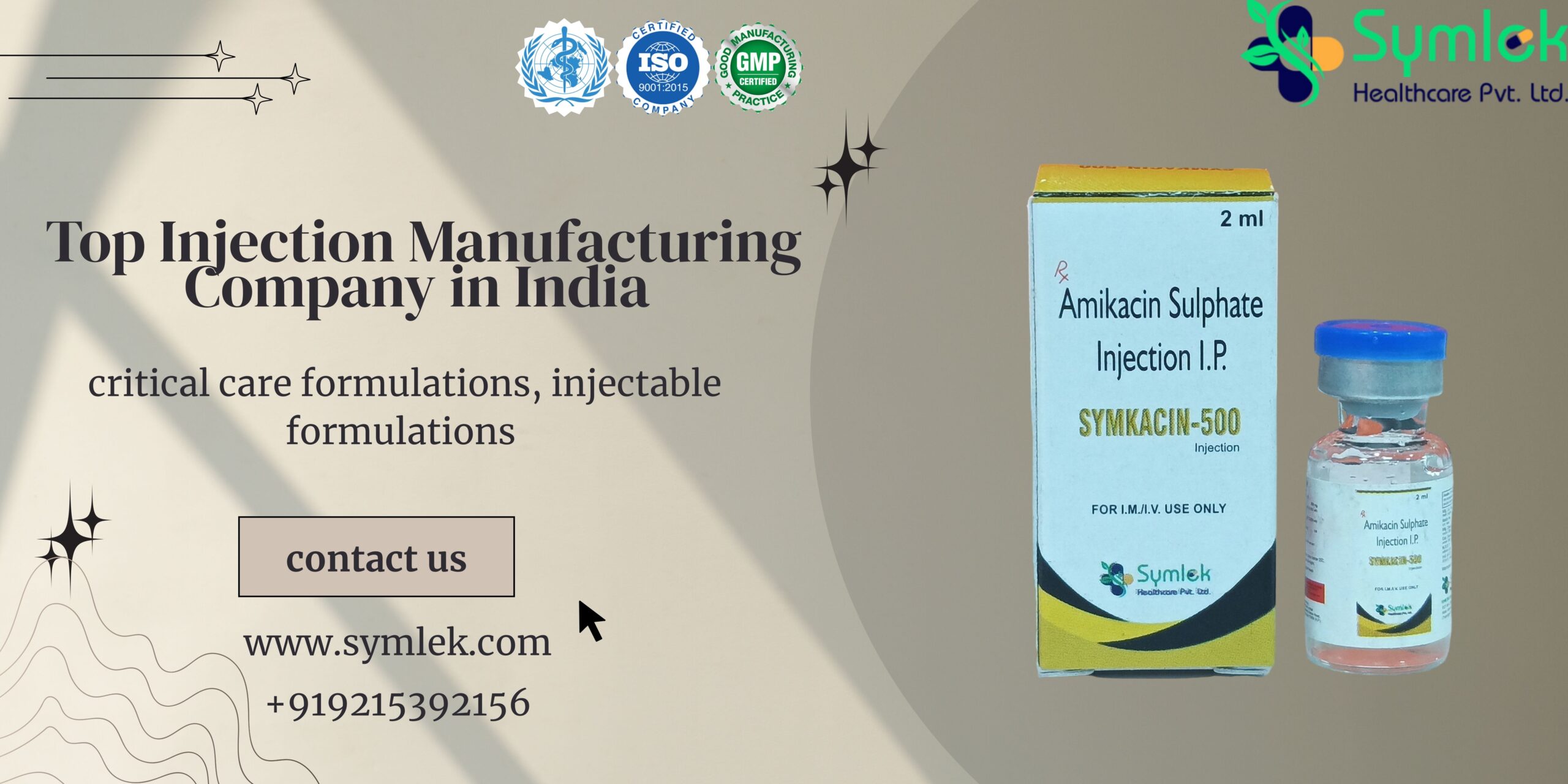

The country has emerged as a leader in the manufacturing of drugs globally, and injectable formulations play an important role in this setup. Is it saving lives by prescribing injections of preventive medicines like antibiotics or the provision of critical care formulations, injectable formulations are always an integral part of the treatment processes. The best injection formulation and Top Injection Manufacturing Company in India always pays emphasis on quality and safety.

Increasing Demand of Injectables in India

Injection preparations have been widely used in hospital or clinic and household emergency treatment due to rapid onset of drug action and high bioavailability. The growing prevalence of chronic diseases and acute infections, along with surgeries, and other critical care, has contributed significantly in demand for quality injectables. The Indian pharma has matched the demand with efficient and affordable injectable formulations.

The good injection manufacturer’s factor includes:

The following characteristics identify one of the Top Injection Manufacturing Company in India:

1. WHO-GMP & International Certifications

The leading injection manufacturers adhere to the WHO-GMP, ISO, and international quality standards. Many injection manufacturers adhere to USFDA, EU GMP, and DCGI standards, making their injections safe, efficient, and exportable.

2. State-of-the-Art

Sophisticated manufacturing facilities, including clean rooms, automated filling machines, and environmentally controlled conditions, are required for all processes of injection manufacturing. Leading manufacturers have invested hugely in technology to ensure sterility, precision, and consistency for each batch produced.

3. Large Portfolio of Injectable Products

The most reliable Injection manufacturers in India offer a variety of injections, including:

- Antibiotic injections

- Anti-inflammatory & analgesic injections

- Critical care injections

- Vitamin & nutritional Injections

- Cardiac & Diabetic injections

- Lyophilised (dry powder) injections

This will bring a wide spectrum, which shall be of importance to hospitals and marketing companies, together with the PCD franchise partners.

4. Strict Quality Control & Assurance

The key to injectable manufacturing is quality. The best injectable goods manufacturers have an in-house quality control laboratory where the following activities are carried out:

- Sterility testing

- Endotoxin testing

- Stability testing

- Physicochemical analysis

- Every lot is strictly tested before sale in the market.

- Significance of Injection Manufacturers in the Health Sector

The injection manufacturers have a critical role in making the healthcare sector of India strong. They provide access to important medications at lower and quality injections; this also affects the healthcare sector of other countries since India exports injections of medication to a number of other nations.

Third Party Manufacturing & Propaganda-cum-Distribution Opportunities

PCD Third-party manufacturing Pharma and PCD pharma Franchise solutions are also provided by most leading injection-based product manufacturers in India. The solutions prove very effective for:

- Pharma startups

- Marketing firms

- Healthcare distributors

Through contract manufacturing, the clients are able to get quality injectable formulations under their labels without having to invest in manufacturing facilities.

Advantages of choosing an Indian injection supplier in India

How to Choose the Top Injection Manufacturing Company in India: A variety of benefits result from choosing the best injection manufacturing company India has to offer:

- Low cost without sacrificing quality production

- Scalable manufacturing capacity

- Expertise in global market regulation

- Timely deliver and supply chain

- Custom packaging and branding solutions

- Advantages ensure that the Indian manufacturers are the market favourite.

- Emphasis on Research & Development

Innovation results in success in the pharmaceutical industry. The leading manufacturers of injection products carry out R&D for better formulation, stability of drugs, and new injection products. R&D activities on a constant basis give effective results and updated meeting medical standards.

Export Performance of Indian Injection Makers

The Indian injection manufacturers have

India is one of the significant exporters of injectable drugs to the Asian region, Africa, Latin America, and the Middle East. Major manufacturing companies for injections followed international regulatory standards and had ensured high documentation standards.

Future Outlook for Injection Manufacturers in India

The future of injection manufacturing in India therefore looks bright for the following reasons:

- Awareness raising within the health care system

- Increased infrastructure in hospitals

- Advances in Critical Care Interventions

- Government incentives towards pharmaceutical manufacturing

Equipped with technology and talent, the potential for increasing the foothold of Indian manufacturers of injections appears to be bright abroad.

Conclusion

Leading Top Injection Manufacturing Company in India stands for the power of trust, quality, innovation, and regulatory excellence. These firms have already started playing a very important role in saving life and bringing better healthcare outcomes with safe, effective, and affordable injectable drugs. For local use, re-exports, and contract manufacturing, India is still trusted for its quality injectable pharmaceutical solutions.